Thermal Imaging Surveys for Commercial & Industrial Properties in London

With over 30 years of experience in thermographic imaging, our team delivers thermal imaging surveys for commercial and industrial buildings across London. We provide a powerful, non-invasive way to detect electrical faults, overheating components, and energy inefficiencies before they cause failure. This proactive approach helps businesses maintain safe, reliable, and compliant electrical systems while reducing the risk of downtime and costly repairs.

Learn more about the electrical faults thermal imaging can detect.

By identifying issues such as loose connections, overloaded switchboards, and failing components early, our thermal imaging surveys support preventative maintenance and improve long-term asset performance across offices, warehouses, factories, retail spaces, data centres, and hospitality venues.

What Is a Thermographic Imaging Survey?

A thermographic survey is a powerful diagnostic tool that uses advanced infrared technology to detect heat anomalies invisible to the naked eye. For businesses across London, it is one of the most effective ways to identify electrical faults, structural issues, and mechanical failures before they escalate into costly problems.

A thermographic imaging survey is essential for businesses across industries including manufacturing, warehousing and logistics, data centres, hospitality and retail, healthcare facilities, and office complexes.

We also carry out thermal imaging surveys for residential complexes and multi-dwelling units across London.

Thermal imaging inspection for insurance plays a critical role in identifying hidden risks that could lead to costly claims. By using advanced infrared technology, insurers and property owners can detect issues such as moisture intrusion, electrical faults, and insulation failures before they cause visible damage. Our thermal imaging inspection services provide clear, documented insights that support underwriting decisions, risk assessments, and claims validation — helping protect both properties and policies.

Contact us directly on 020 8455 9020 to get a rough idea of cost and timeframe.

Quick turnaround?

A member of our team will call you back to answer all your commercial and industrial electrical service enquires.

- Barbican

- Farringdon

- Finchley

- Hendon

- Harrow

- Westminster

- Holborn

- Finsbury Park

- Islington

- Enfield

- Richmond

- Hammersmith

- Ealing

- Holloway

- Muswell Hill

- Mill Hill

How We Conduct a Thermal Imaging Survey in London

-

1

Visit

One of our thermographers will visit your site at a time that suits you, providing an estimation and time frame at no cost.2Survey

We conduct a detailed thermographic imaging survey, capturing key data and documenting each electrical panel with infrared (IR) and digital (DC) imaging.3Report

After the survey, we deliver a comprehensive IR thermography report within 72 hours, highlighting urgent issues. Expedited reports are available for emergencies.

How Much Does a Thermal Imaging Survey Cost in London?

Thermal imaging survey costs vary depending on the scope and complexity of the inspection. Rather than publish fixed prices that may not reflect your specific requirements, we prefer to give you an honest, accurate estimate based on your property and needs.

The main factors that affect the cost of a thermal imaging survey:

- Size of the property — A small retail unit requires significantly less time than a large warehouse or multi-floor office building. Survey time directly affects the overall cost.

- Number of electrical panels and distribution boards — Each panel requires individual inspection and documentation with both infrared and digital imaging. More panels means a longer survey and more detailed reporting.

- Type of systems being inspected — A survey covering electrical systems only is priced differently to one covering mechanical plant, HVAC, and building fabric in addition to electrical.

- Access requirements — Sites that require out-of-hours access, specialist equipment, or additional health and safety considerations may affect the overall cost.

- Report requirements — Our standard thermographic report is delivered within 72 hours. Expedited reports for urgent situations are available at an additional cost.

With over 30 years of experience carrying out thermal imaging surveys across London, we provide straightforward, honest pricing with no hidden costs. Call us on 020 8455 9020 for a no-obligation estimate.

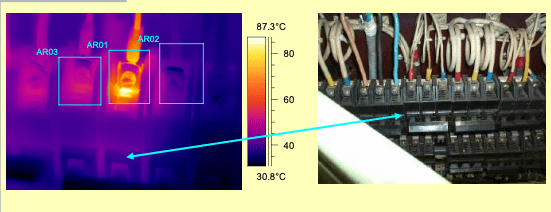

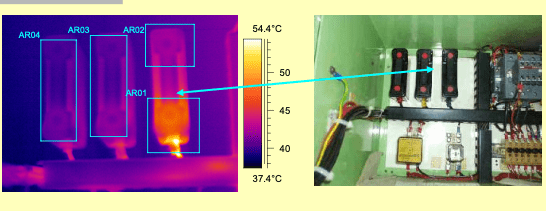

Common Electrical Issues Detected by Thermal Imaging

Thermal scans can detect oxidation in connectors before it causes resistance or system failure, keeping your electrical setup running smoothly.

Problems a Thermographic Survey Can Identify

Thermal imaging for electrical systems plays a crucial role in enhancing safety and spotting potential issues before they escalate. Regular inspections of power and lighting distribution boards, every six months, annually, or biennially, are essential to maintain system integrity.

Many insurance providers mandate thermal imaging surveys to minimise risks, particularly in commercial properties across London.

Over time, vibration and thermal stress can cause connections in power distribution systems to loosen, while contamination may lead to corrosion. These issues increase resistance at connection points, making them prone to overheating.

Left unaddressed, this could result in a dangerous condition that generates excessive heat without triggering circuit protection.

Fire Prevention — Faulty or overloaded circuits can spark, overheat, melt insulation, and potentially ignite a fire. Thermographic imaging inspections detect these issues early, enabling repairs or replacements before significant damage occurs.

This proactive approach minimises downtime, prevents costly repairs, and ensures the safety of your facility. Incorporating thermal inspections into a regular condition-based monitoring programme is the most effective way to maintain predictive and preventative maintenance. We offer tailored thermal imaging monitoring programmes for London-based facilities, with reminders to ensure inspections are carried out on time.

Thermal Imaging Surveys for Insurance Purposes

An increasing number of commercial insurance providers now require regular thermal imaging surveys as a condition of cover. For properties with complex electrical systems, high energy demands, or significant fire risk — including data centres, manufacturing facilities, warehouses, and hospitality venues — a documented thermographic inspection report is no longer optional. It is a requirement.

Our thermal imaging surveys for insurance purposes provide clear, detailed infrared and digital imaging reports that meet insurer requirements and support underwriting decisions, risk assessments, and claims validation.

What an insurance thermal imaging report covers:

Electrical distribution boards and panels, switchgear and circuit breakers, cable terminations and connections, mechanical plant and equipment, and any other systems specified by your insurer or loss adjuster.

Why insurers require thermal imaging:

Electrical faults are one of the leading causes of commercial property fires in the UK. Thermographic imaging identifies these faults before they cause damage — reducing the insurer’s risk exposure and demonstrating that the property owner has taken reasonable steps to maintain a safe, compliant building.

What you receive:

A comprehensive Level 2 certified thermographic inspection report delivered within 72 hours, documenting all findings with infrared and digital images, risk classifications, and recommended remedial actions. This report is accepted by major commercial insurers and can be provided directly to your broker or loss adjuster.

If your insurer has requested a thermal imaging survey or you want to get ahead of the requirement, contact us on 020 8455 9020.

Mechanical & Industrial Thermographic Imaging Surveys in London

Infrared thermography is an effective tool for predictive maintenance in industrial environments. By detecting heat patterns emitted by objects, it helps operators identify potential issues or inefficiencies in machinery before they lead to significant damage or costly downtime.

For example, a manufacturing plant using thermographic imaging to inspect electrical panels and switchgear can identify a hotspot on a circuit breaker, indicating excessive resistance and potential failure, and replace the faulty component before it leads to an electrical fire or power outage.

A commercial building using infrared thermography to inspect HVAC ductwork can identify hot and cold spots indicating air leaks and inefficient insulation, reducing heating and cooling costs significantly.

Regular infrared inspections of mechanical rotating equipment identify excess heat caused by friction and wear. An increase above typical operating temperatures is a leading indicator of component failure, thermal imaging detects these anomalies early, allowing maintenance teams to act before a catastrophic failure occurs.

Data Centre Thermal Imaging Inspections for Reliability & Safety

A data centre relies on uninterrupted operation to ensure seamless digital services. Thermal imaging is used to monitor server racks, power supplies, and cooling systems, detecting any abnormal heat patterns that could indicate potential issues.

During a routine thermographic survey for data centres, an overheating power unit can be identified before it leads to power supply failure, system crashes, or downtime for critical applications. Regular thermal imaging inspections help prevent unexpected failures, optimise energy efficiency, and extend the lifespan of expensive IT infrastructure.

In a data centre where uptime is everything, predictive maintenance through thermographic imaging is an essential tool for reliability and risk reduction. Find out more about our thermal imaging surveys for data centres.

Certified Thermographic Imaging — 30 Years of Experience

With over 30 years of experience delivering thermographic imaging surveys across London, our highly qualified thermographers consistently deliver precise and reliable thermographic inspection reports. With Level 2 certification, our trained engineers excel in troubleshooting and calibrating equipment, ensuring accurate data interpretation and comprehensive reporting.

Our thermal imaging survey services include:

- Level 2 Thermographic Certification

- Level 2 Qualified Thermographer’s

- Large-Format FLIR Cameras

- Detailed, Easy-to-Follow Thermal Imaging Reports

Level 2 certified thermal engineers deliver higher-quality thermographic electrical surveys and ensure greater technical consistency. Uncertified or lower-level thermographers are more prone to errors that can be costly and potentially hazardous — such as overlooking critical issues that could lead to equipment failure or fire.

While appropriate qualifications are crucial, implementing written inspection procedures is also vital for achieving high-quality results and consistent reporting.

Thermographic Imaging Surveys Across London

We deliver thermal imaging surveys and thermographic inspection services for commercial and industrial properties across London including the City of London, Canary Wharf, Westminster, Islington, Camden, Hackney, Southwark, Hammersmith, Kensington, Mayfair, Barnet, Enfield, and the wider Greater London area.

Whether you need a one-off thermographic survey or an ongoing condition-based monitoring programme, our team is ready to help. Contact us today on 020 8455 9020.

Frequently Asked Questions About Thermal Imaging Surveys

How much does a thermal imaging survey cost in London?

The cost of a thermal imaging survey depends on several factors including the size of the property, the number of electrical panels and distribution boards to be inspected, and the complexity of the site. For a rough idea of cost and timeframe, contact us directly on 020 8455 9020 — we’ll give you an honest estimate with no obligation.

How long does a thermal imaging survey take?

Most commercial thermal imaging surveys take between two and four hours depending on the size of the site and the number of systems being inspected. Larger industrial facilities or data centres may require a full day. We’ll always give you a realistic timeframe before we begin.

How often should I get a thermal imaging survey?

For most commercial properties we recommend an annual thermal imaging survey as a minimum. High-risk environments such as data centres, manufacturing facilities, and healthcare buildings benefit from inspections every six months. Many insurance providers also stipulate a minimum inspection frequency — we can advise on what’s appropriate for your specific property and sector.

Is a thermal imaging survey required for insurance?

Many commercial insurance providers now require or strongly recommend regular thermal imaging surveys as a condition of cover, particularly for high-risk properties. A documented thermographic inspection report provides evidence of due diligence and can support claims validation if an issue arises. We provide detailed reports within 72 hours of survey completion.

What is the difference between thermal imaging and thermographic imaging?

The two terms refer to the same process. Thermal imaging is the commonly used everyday term while thermographic imaging is the technically precise, industry-standard terminology used by certified engineers and insurers. Our surveyors are Level 2 certified thermographers with over 30 years of experience in both commercial and industrial environments.

How quickly will I receive my thermal imaging report?

We deliver all thermographic inspection reports within 72 hours of the survey. For urgent situations, expedited reports are available — contact us to discuss your requirements.

Can thermal imaging detect problems that a standard electrical inspection misses?

Yes. A standard electrical inspection is visual and requires systems to be isolated. Thermal imaging surveys are carried out while systems are live and under load, detecting heat anomalies that are invisible to the naked eye and undetectable through standard inspection methods. This makes thermographic surveys an essential complement to regular EICR testing.