Top 5 Signs Your Commercial Electrical System Needs an Upgrade

In the fast-paced world of commercial and industrial business, a reliable electrical system is the backbone of daily operations. But many businesses overlook the warning signs that their electrical infrastructure might be outdated or struggling to keep up. Ignoring these signs can lead to costly downtime, safety risks, and inflated energy bills.

If you’re wondering whether your commercial electrical system is due for an upgrade, here are the top five signs to watch out for:

- Frequent Circuit Breaker Trips

- Flickering or Dimming Lights

- Rising Energy Bills

- Equipment Malfunctions

Frequent Circuit Breaker Trips or Power Outages

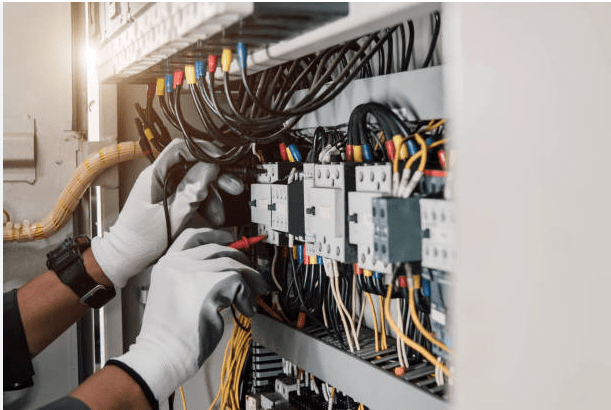

If your breakers are regularly tripping or you experience sudden power cuts, it’s a clear indication that your electrical system is overloaded or faulty. Older wiring and outdated circuit breakers may not handle the load of modern equipment, leading to interruptions that disrupt productivity and pose safety hazards.

In the UK, Electrical Safety First reports that overloaded circuits and faulty installations are a leading cause of electrical fires in commercial premises. Older systems, especially those installed before the 2000s, were never designed to handle today’s energy demands, particularly with businesses running high-powered machinery, HVAC systems, servers, and EV charging points.

Outdated circuit protection devices may also fail to detect modern fault conditions like arc faults or transient surges. This increases the risk of fire or shock and causes regular downtime, costing your business in lost productivity and reactive repair expenses.

A professional electrical system upgrade will include modern MCBs, RCBOs, surge protection devices, and load balancing, all tailored to your operational needs. This ensures your system runs safely, reliably, and efficiently, even as your business grows.

Flickering or Dimming Lights

Lights that flicker or dim unexpectedly are often a symptom of voltage fluctuations or failing wiring. This not only affects workplace comfort but could signal dangerous electrical issues that might escalate if left unaddressed.

Choosing the right inverter drive is just the first step, but ensuring compatibility with your existing control systems is crucial for seamless upgrades and maximising performance.

Learn more about our control system upgrades and how we ensure perfect inverter drive compatibility on our Control Panel Services page.

Rising Energy Bills Without Increased Usage

A sudden increase in electricity costs, without any change in your business operations, can point to inefficiencies in your electrical system. Outdated equipment, poor wiring, or inefficient motor controls can waste energy, driving up your bills unnecessarily.

For example, motors consume over 60% of the total electricity used in industrial facilities, according to the International Energy Agency. If those motors are running without inverter drives (VFDs) or proper controls, they could be consuming up to 50% more energy than necessary, particularly in applications like pumps, fans, or conveyors where speed variation is key.

Likewise, old fluorescent or halogen lighting can use up to 80% more power than LED alternatives. And poor power factor correction or overloaded circuits can further increase your demand charges.

In one real-world case, a mid-size warehouse saved over £4,000 annually simply by upgrading its lighting system and fitting inverter drives to its ventilation fans. These types of changes typically pay for themselves within 1–2 years.

If your energy bills have crept up with no clear reason, it’s likely your system isn’t working as efficiently as it should, and every month you delay is more money lost.

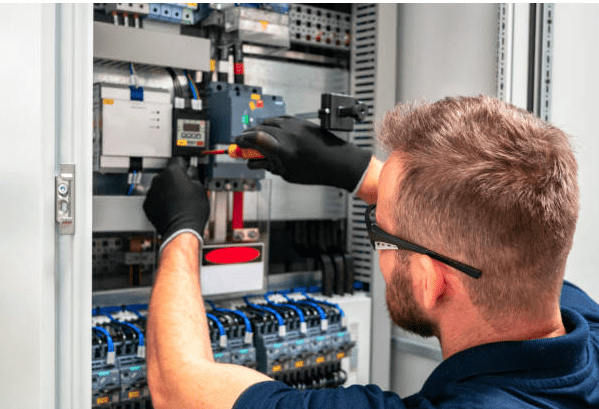

Equipment Malfunctions or Frequent Repairs

If your machinery or electrical devices are frequently breaking down, overheating, or behaving unpredictably, your electrical supply may be to blame. Unstable voltage, poor power quality, and insufficient capacity can place unnecessary strain on sensitive equipment, leading to failures, safety issues, and unplanned downtime.

According to GAMBICA (the UK’s trade association for industrial automation), power quality issues account for up to 30% of all equipment failures in industrial settings. Common culprits include voltage sags, harmonics, and poor grounding, which is often due to the result of outdated or overloaded electrical infrastructure.

The Carbon Trust also reports that poorly maintained motors and electrical systems can reduce equipment lifespan by up to 50%, while increasing energy consumption significantly. For businesses running 24/7 operations, even minor inefficiencies can result in thousands of pounds lost annually in repairs, wasted energy, and production delays.

Worse still, repeated breakdowns often signal an underlying system-wide issue.

Not just a problem with the equipment itself. Upgrading your commercial electrical system can stabilise voltage, balance loads properly, and protect your valuable assets from unnecessary wear and tear.

Your System Is More Than 20 Years Old

If your electrical system is over 20 years old, it’s likely falling behind both in terms of safety and performance. Electrical standards and technology have advanced significantly in the last two decades, and older systems often lack the capacity, protection, and efficiency needed to support modern equipment and business operations.

For instance, regulations such as the 18th Edition of the IET Wiring Regulations (BS 7671) now require more advanced protection measures, including RCD protection for socket outlets, arc fault detection devices, and specific provisions for energy efficiency and surge protection. Systems installed before these updates may not comply, putting your business at risk during inspections or insurance claims.

From a performance standpoint, older distribution boards, wiring, and switchgear may not handle the higher electrical loads demanded by today’s machines, IT infrastructure, or automated systems. This can lead to overheating, voltage drops, and even fire hazards. The Electrical Safety First organisation highlights that aging electrical systems are a leading cause of commercial fires in the UK.

Upgrading your system doesn’t just bring it up to code.

It also opens the door to energy-efficient solutions like LED lighting, smart metering, and inverter drives. These upgrades can reduce electricity consumption by up to 30%, extend equipment life, and help your business hit net zero or sustainability targets.

we specialise in commercial and industrial electrical services, offering expert assessments and tailored upgrade solutions. If you recognise any of these signs or want peace of mind, get in touch for a comprehensive electrical health check.