Warehouse Thermal Imaging

Warehouse Safety and Compliance in the UK

The Importance of Electrical Safety in Warehouses

Regulatory Compliance and Safety Standards

The Role of Electrical Thermal Imaging

Preventative Maintenance and Equipment Monitoring

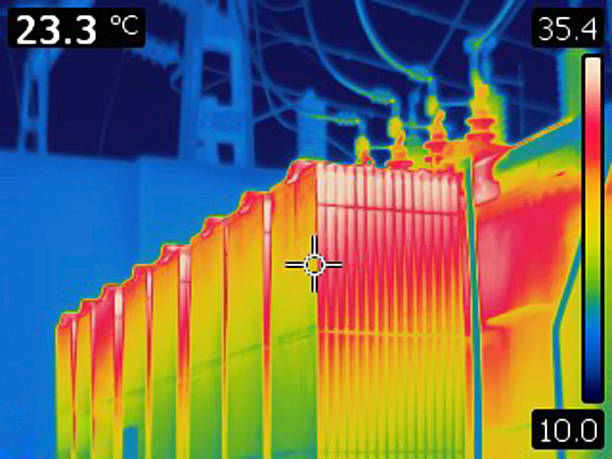

Incorporating thermal imaging into routine maintenance protocols allows for the early detection of equipment anomalies such as overheating motors or electrical faults. Identifying these issues before they escalate can prevent costly equipment failures and unplanned downtime, thereby optimizing operational efficiency.

Fire Detection and Safety Enhancement

Warehouses are susceptible to fire hazards due to the storage of various materials, some of which may be flammable. Thermal imaging cameras can detect hotspots and unusual temperature elevations that may precede fires, providing early warnings and enhancing fire prevention strategies. This early detection capability is crucial for safeguarding assets and ensuring the safety of personnel.

Security and Intrusion Detection

Thermal imaging technology is highly effective in security applications, especially in low-light or no-light conditions. Unlike traditional CCTV systems that rely on visible light, thermal cameras detect heat signatures, making it possible to identify unauthorized personnel or intruders regardless of lighting conditions. This enhances the overall security posture of warehouse facilities.

How Thermal Imaging Will Detect Warehouses Issues

1. Unplanned Downtime and Operational Disruptions

Electrical faults can bring warehouse operations to a standstill, halting conveyor systems, lighting, or essential machinery. Even a short disruption can result in delayed shipments, reduced productivity, and dissatisfied clients.

Solution: Regular thermal imaging inspections help detect overheating components early, enabling proactive maintenance without the need to shut down operations. This minimises downtime and keeps the warehouse running efficiently.

2. High Repair and Replacement Costs

When minor faults go undetected, they can evolve into severe failures, requiring costly repairs or complete equipment replacements. Sourcing spare parts or arranging emergency maintenance adds to expenses and delays.

Solution: Thermal imaging surveys identify early warning signs of electrical deterioration, allowing maintenance teams to address issues before they become critical. This helps control maintenance costs and avoid expensive replacements.

3. Safety Hazards and Compliance Issues

Warehouses often store flammable materials, making electrical faults particularly hazardous. An overheating electrical panel or overloaded circuit can trigger fires, risking employee safety and damaging valuable stock.

Solution: Implementing regular thermal imaging checks helps spot heat anomalies that could indicate electrical hazards. Early detection supports compliance with health and safety regulations, reducing the risk of fire and liability.

Warehouse Maintenance with Thermal Imaging

Thermal imaging should be an integral part of warehouse maintenance strategies. Inspecting electrical panels, switchgear, control boxes, lighting circuits, and automated machinery with thermal imaging cameras provides clear, visual evidence of overheating or faulty components.

Proactive maintenance through thermal imaging not only prevents unexpected breakdowns but also extends the lifespan of your equipment. This results in reduced maintenance costs and uninterrupted operations, vital for meeting logistics demands and client expectations.

DO YOU NEED A

thermographic Survey?

We’re Fully Licensed

Manufacturing Plants

Facilities with complex electrical systems rely on thermographic surveys to identify overheating that could disrupt production.

Data Centres

Thermographic surveys are essential for detecting hotspots, ensuring uptime, and preventing costly equipment failures.

Warehouses/ Distribution Centres

Extensive lighting, conveyor belts, and electrical panels, require thermal imaging surveys for spotting electrical faults.

Healthcare Facilities

Critical infrastructure like power systems, medical equipment, and HVAC units benefit from regular thermal scans.