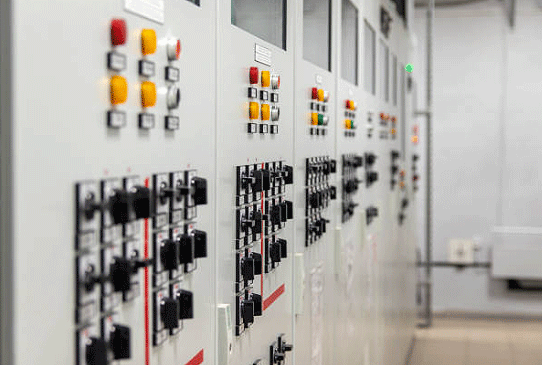

Control Panel Installation Services

DB Site Services delivers expert control panel design, installation, and upgrades tailored to your operational needs. Our skilled team specialises in custom wiring, PLC panel setups, and electrical panel enhancements that boost both safety and efficiency. From routine maintenance to full-scale safety upgrades, we provide reliable solutions for all your industrial electrical systems.

Diagnosing, repairing, and maintaining control systems

Electrical Control Panels Built Right from the Start

Installing a control panel isn’t just a technical job; rather, it’s a vital part of keeping industrial systems running safely and efficiently. To begin with, the process starts with initial planning, where accuracy and foresight set the foundation. Next, each stage from wiring to assembly demands precision, experience, and an eye for detail. Finally, during the last phase, thorough inspection ensures the system operates as intended. In short, here’s a behind-the-scenes look at how our team at DB Site Services approaches commercial and industrial control panel installation.

Step 1: Smart Planning & Tailored Design

Every successful installation begins with a solid plan. First, we identify the exact requirements of the system — what type of control panel is needed, which components are essential, and where it should be located. In addition, accessibility, long-term maintenance, and safety are all factored in from the beginning so that the panel serves its purpose effectively. Finally, for more details on how we plan and deliver high-quality systems, visit our Control Panel Design and Build page.

Step 2: Preparing the Site

Before installation begins, we get the workspace ready. That means clearing the area, setting up tools, and verifying that all materials and components are on hand. A well-organised site makes for a smooth, safe build. All materials are sourced from trusted manufacturers that we’ve worked with for decades, rest assured they will be arrive promptly and work efficiently.

Step 3: Mounting with Precision

With planning and prep complete, it’s time to mount the panel. Whether wall-mounted or free-standing, we ensure it’s stable, level, and properly grounded, laying the foundation for long-term reliability and safety. We have installed dozens of control panels from analogue to digital, keeping in mind all the key aspects of functionality. Allocating the right space and position the control panel is pivotal in productive day to day usage.

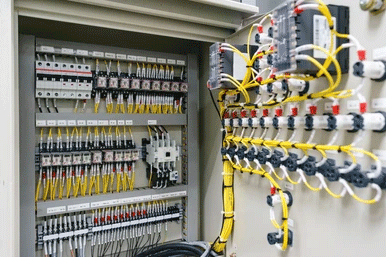

Step 4: Clean, Organised Wiring

Next comes the wiring. All internal connections, including power sources, motors, sensors, and other inputs and outputs, are installed with care. Moreover, neat and well-labelled wiring is not just good practice; it improves safety, simplifies maintenance, and makes future upgrades much easier.

In addition, our team is experienced in prevention methods that ensure you have all the correct measures in place to keep your business switched on and regulated.

Step 5: Installing Internal Components

Once wired, we fit all control devices, relays, PLCs, and breakers into place. Everything is connected according to the design spec and double-checked for accuracy before testing begins.

Step 6: Testing & Commissioning

Before a panel goes live, we carry out full testing and commissioning. This includes in-circuit checks and simulations to confirm each component is working exactly as it should. Any issues are resolved here, before the system is put into operation. As part of our commitment to long-term reliability, we also recommend regular Electrical Fault Prevention and Thermal Imaging to identify potential issues early and minimise downtime.

Step 7: Final Quality Check

The last step is a detailed inspection. We verify every element: connections, layout, function, safety measures, and compliance. Only once it meets our highest standards do we hand it over, confident it’s ready for action.

Key Types of Electrical Control Panels

Motor Control Centres (MCCs)

Used primarily in industrial environments, MCCs provide a centralized system for controlling and monitoring multiple electrical motors. As a result, they improve operational efficiency and enhance safety by organizing motor control in one accessible location.

Programmable Logic Controller (PLC) Panels

PLC panels automate complex industrial processes by receiving, processing, and responding to input signals. Consequently, these panels are essential for precise control and decision-making in both electrical and electronic circuits.

Automatic Mains Failure (AMF) Panels

AMF panels ensure continuous power by automatically switching from the main power supply to a backup generator during outages. As a result, they are critical for maintaining power to essential equipment and operations without manual intervention.

Power Control Centre (PCC) Panels

PCC panels manage the distribution of electrical power from the main source to various sub-panels, systems, and machinery. In fact, they are commonly used in industrial facilities because they help streamline operations and safeguard power flow.